Understanding Filling Machines

What Are Filling Machines?

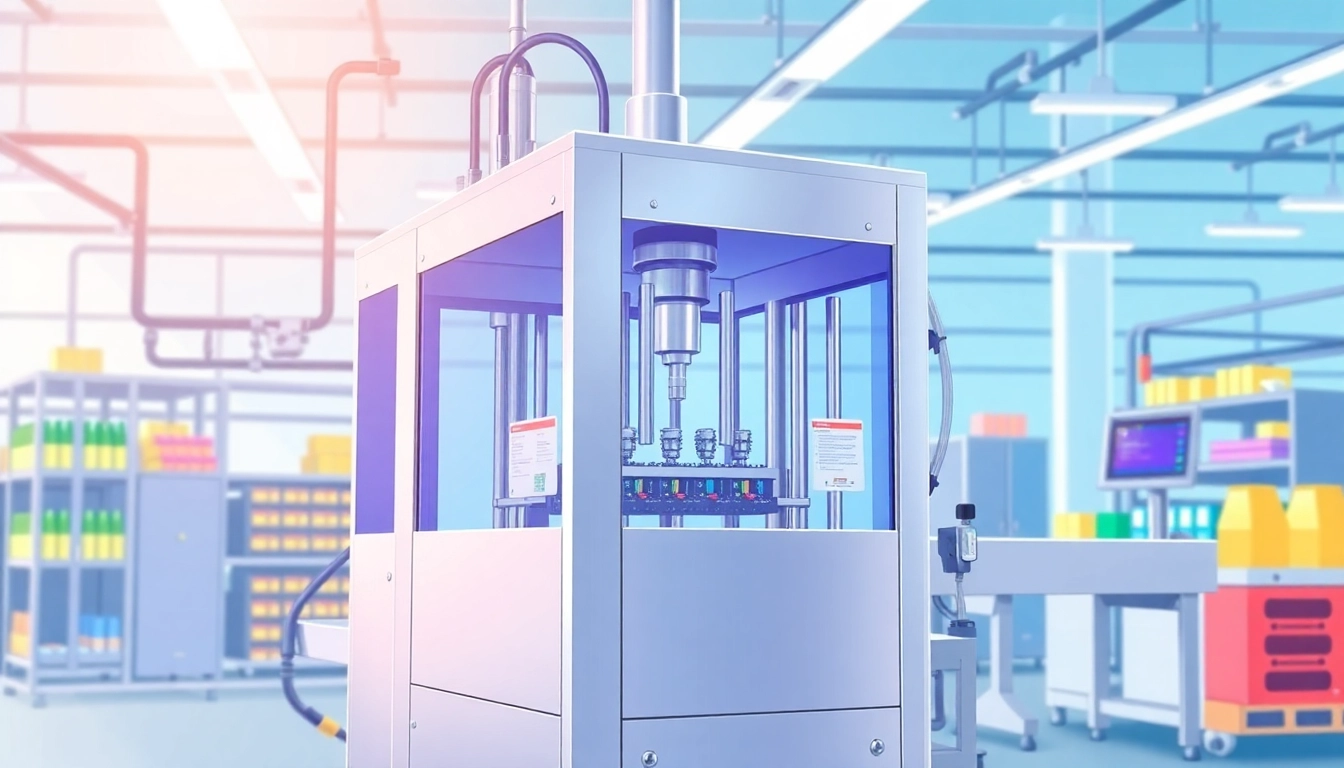

Filling machines are essential equipment in the manufacturing and packaging industries, designed to accurately fill containers with liquids, powders, or granulated products. These machines eliminate the manual process of filling, significantly increasing efficiency and consistency in production lines, catering to various sectors, including food and beverage, pharmaceutical, chemical, and cosmetic industries. The core function of a filling machine is to ensure that each container receives a precise volume of product, which minimizes wastage and ensures product quality. Filling Machine Manufacturers offer a wide variety of filling machines to meet the distinct needs of different applications.

Types of Filling Machines

The types of filling machines can broadly be categorized based on their mechanisms, applications, and container types. Here are some common varieties:

- Volumetric Filling Machines: These machines dispense a specific volume of liquid or powder, relying either on gravity or positive displacement mechanisms to achieve accuracy.

- Piston Filling Machines: Ideal for thicker liquids, these machines utilize a piston to pull product into a cylinder, which is then released into the container.

- Gravity Filling Machines: These are simple machines where the product flows down from a tank into the container via gravity, suitable for thin liquids.

- Aseptic Filling Machines: Used in food and beverage industries, aseptic machines fill sterilized products into sterilized containers in a sterile environment, ensuring long shelf life.

- Semi-Automatic and Fully Automatic Filling Machines: Depending on production requirements, manufacturers can opt for machines that reduce human intervention through automation.

Applications Across Industries

Filling machines are employed in numerous industries with varying applications:

- Food and Beverage: Used for filling liquids, sauces, jams, and solid products like grains or nuts.

- Pharmaceutical: Essential for filling medications and syringes with precise dosages, ensuring quality control.

- Chemicals: Suitable for filling hazardous or non-hazardous substances, varying bottle sizes and shapes.

- Cosmetics: Filling creams, lotions, and other beauty products to ensure consistency and hygiene in packaging.

Choosing the Right Manufacturer

Key Factors to Consider

When selecting a filling machine manufacturer, several crucial factors should be taken into account:

- Experience and Expertise: Look for manufacturers with a proven track record in delivering reliable and efficient filling solutions tailored to your industry.

- Customization Options: Different production lines may need customized machines to meet specific filling requirements.

- Technical Support: Providers that offer robust after-sales service and technical support can help maintain machine performance.

- Quality of Components: The quality of materials used in manufacturing the filling machines is directly related to the machine’s reliability and longevity.

- Budget and ROI: A balance between upfront cost and potential long-term return on investment is essential; a higher-quality machine may translate to lower maintenance and operational costs over time.

Evaluating Manufacturer Reputation

Evaluating the reputation of filling machine manufacturers is essential. Key measures to assess include:

- Customer Reviews: Compile feedback from previous clients to gauge satisfaction levels and performance history.

- Certifications: Check if the manufacturer has necessary certifications like ISO, which signify adherence to quality standards.

- Case Studies: Request case studies that showcase successful implementations of their filling machines in similar industries.

- Industry Presence: A manufacturer’s involvement in industry exhibitions and trade fairs often indicates commitment to innovation and market trends.

Comparative Analysis of Top Brands

Examining and comparing the offerings of top filling machine brands can also provide insights for selection:

- Accutek Packaging Equipment: Known for a wide range of machines, from filling to capping, focusing on custom solutions.

- Cozzoli Machine Company: This company specializes in liquid filling, offering robust machines built for various sectors.

- Volumetric Technologies: Offers reliable American-made filling systems, often emphasizing innovation and quality.

- E-PAK Machinery: Manufacturers focusing on aeration and product quality, primarily serving the bottling industry.

- Fogg Filler: Known for high-quality rinsing and capping equipment, specifically for free-flowing liquids.

Innovations in Filling Machine Technology

Automation Trends in Filling Systems

Automation is a critical trend reshaping filling machine technology. The shift capitalizes on advanced technology to enhance efficiency and reduce human error in filling processes. Key aspects include:

- Programmable Logic Controllers (PLCs): These offer flexibility and control over the filling parameters, allowing manufacturers to optimize the production process.

- Robotics and AI: The integration of robotics can manage complex filling lines, improving productivity and safety.

- Data Collection: Modern filling machines collect data for process improvements, enabling predictive maintenance and efficient resource allocation.

Sustainability Practices by Manufacturers

With rising awareness of environmental issues, manufacturers are increasingly adopting sustainable practices. This involves:

- Eco-Friendly Materials: Shifting to biodegradable materials for packaging and machine components.

- Energy Efficiency: Designing machines that consume less energy while maintaining high performance.

- Waste Reduction: Implementing systems to minimize waste during filling and packaging processes.

Integration of Smart Technology

The concept of smart technology in filling machines involves using IoT devices, enabling machines to communicate and share data. Benefits include:

- Remote Monitoring: Operators can monitor and control machine functions remotely, leading to faster response times.

- Predictive Maintenance: Using analytics to predict machine failures before they occur can minimize downtime.

- Real-Time Quality Control: Smart sensors can detect anomalies during the filling process, ensuring that any variations from specifications are corrected immediately.

Case Studies: Success Stories of Filling Machine Implementation

Industry-Specific Examples

Real-world examples of companies efficiently using filling machines provide valuable insights:

- Food Industry: A leading beverage manufacturer integrated a high-speed filling system that reduced labor costs by 30% while increasing output by 50%.

- Pharmaceuticals: A pharmaceutical company employed piston filling machines to ensure accurate dosages, leading to a 20% decrease in wastage.

- Cosmetics: A skincare brand switched to an automatic filling solution, cutting down on manual filling time by 60% and significantly improving consistency.

Cost Efficiency and Productivity Gains

Modern filling machines are designed to optimize productivity:

- Labor Efficiency: Automation reduces the workforce needed for filling, allowing companies to allocate human resources elsewhere.

- Minimized Downtime: With advanced diagnostics and quick changeover capabilities, modern machines can operate longer periods without interruption.

- Quality Output: Consistency and accuracy lead to better final products, enhancing customer satisfaction and trust.

Testimonials from Key Users

User testimonials from industry leaders often highlight the advantages of investing in quality filling machines:

“Implementing a new filling line allowed us to achieve greater operational efficiency and meet market demands more swiftly.” – Operations Manager, Beverage Company

“The automatic filling systems we invested in have paid for themselves through significantly reduced wastage alone.” – Production Specialist, Pharmaceutical Firm

The Future of Filling Machine Manufacturing

Predicted Market Trends

The future of filling machine manufacturing holds promising avenues, influenced by technological advancements and market demands. Expected trends include:

- Increased Automation: More companies will lean toward fully automated lines to enhance efficiency and maintain competitive edges.

- Customization Needs: The need for bespoke filling solutions that cater to unique products will grow, driving innovation in design.

- Global Supply Chain Optimization: Companies will seek to streamline operations to mitigate risks, particularly in uncertain market conditions.

Challenges Facing Manufacturers

Manufacturers must navigate various challenges to stay ahead:

- Technological Adaptation: Keeping pace with rapid technological advancements can prove challenging and requires continuous training for staff.

- Regulatory Compliance: Adhering to strict industry regulations can add complexity to production processes and design requirements.

- Market Competition: As new entrants join the market, existing manufacturers need to innovate continually to maintain their market position.

Opportunities for Growth and Innovation

Despite these challenges, significant growth opportunities exist:

- Integration with Industry 4.0: Smart machinery that connects with supply chains and production lines can significantly enhance efficiency and adaptability.

- Collaboration with Tech Firms: Partnering with technology innovators can lead to groundbreaking developments in machine capabilities.

- Expansion into Emerging Markets: With rising demand in emerging economies, there is a vast potential for manufacturers to expand their customer base.